5-AXIS MACHINING CENTERS

5-AXIS MACHINING CENTERS

A CNC lathe or metalworking lathe is a large class of lathes designed for precisely machining relatively hard materials. They were originally designed to machine metals; however, with the advent of plastics and other materials, and with their inherent versatility, they are used in a wide range of applications, and a broad range of materials.

DNM SERIES

The DNM 350 5 axis, equipped with the FANUC F31i-A5 control, is designed for a wide range of applications, especially prismatic type work pieces. It is capable of full 5 axes[4+1 axes] simultaneous machining, greatly reducing the need for multiple setups and increasing the precision of the finished work piece. The powerful, 12,000 rpm high speed spindle provides superior performance in virtually any machining application.

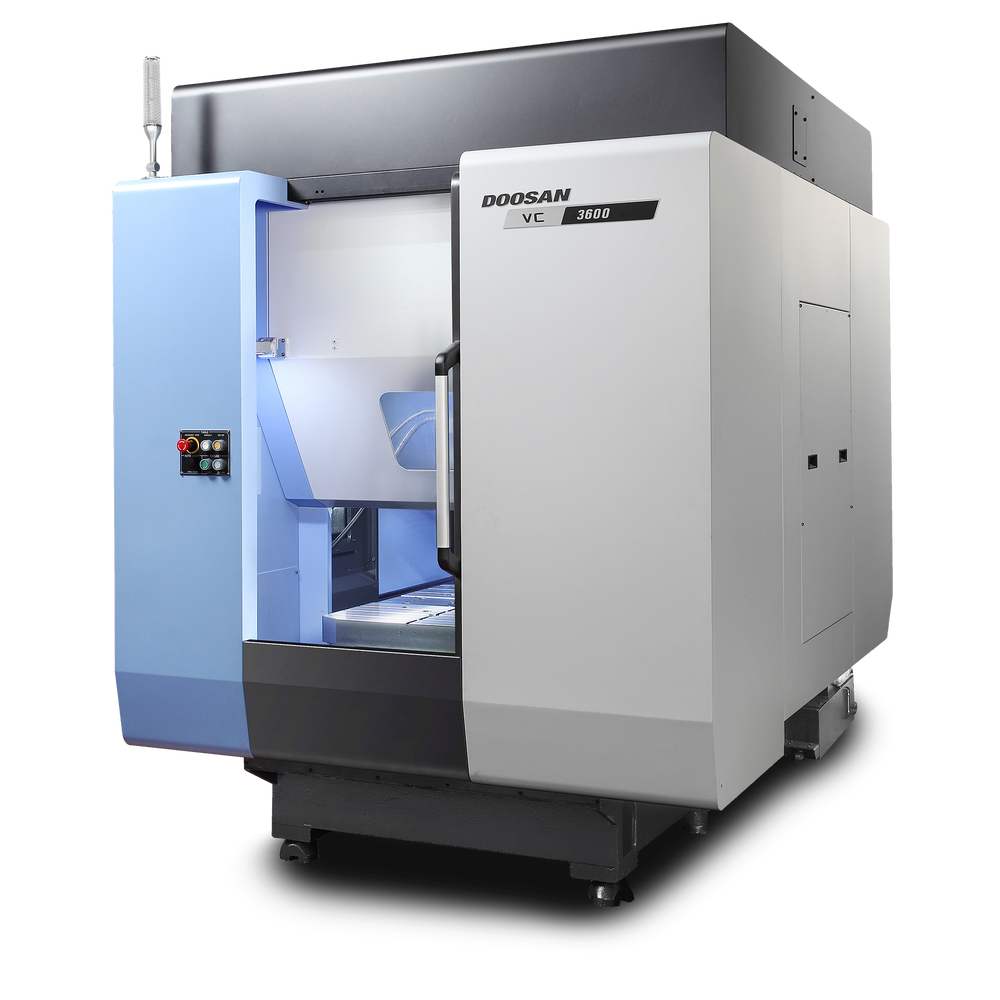

DNM 5AX SERIES

Say hello to the foot in the door. The first time you machine complex parts in a single setup, you never go back. That’s because the time, money and operator error you save instantly changes the way your shop does business. Sporting high rigidity roller guides for all axes, the DNM 5AX will take you where you want to go.

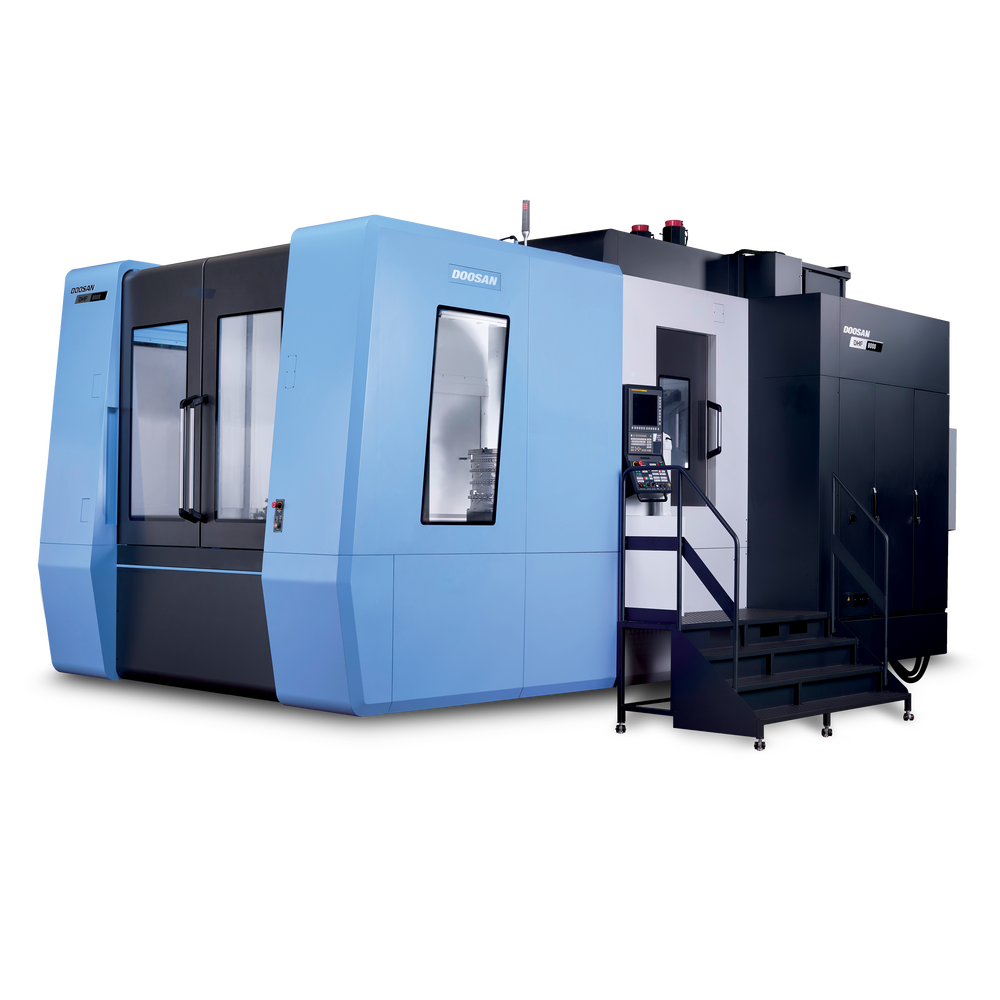

DHF SERIES

Calling all Aerospace, Oil Field and Automotive shops. Thanks to its robust design, 800mm twin pallets, built-in precision and minimum footprint, the DHF 8000 gobbles up large part applications in aerospace, oil field, automotive and other industries. Complex parts are handed with the utmost efficiency.

Benefits of CNC Machining

Over 50 Years of Experience and Service!

You can depend on Adams Machinery for assistance in determining what machine will best fit your needs.