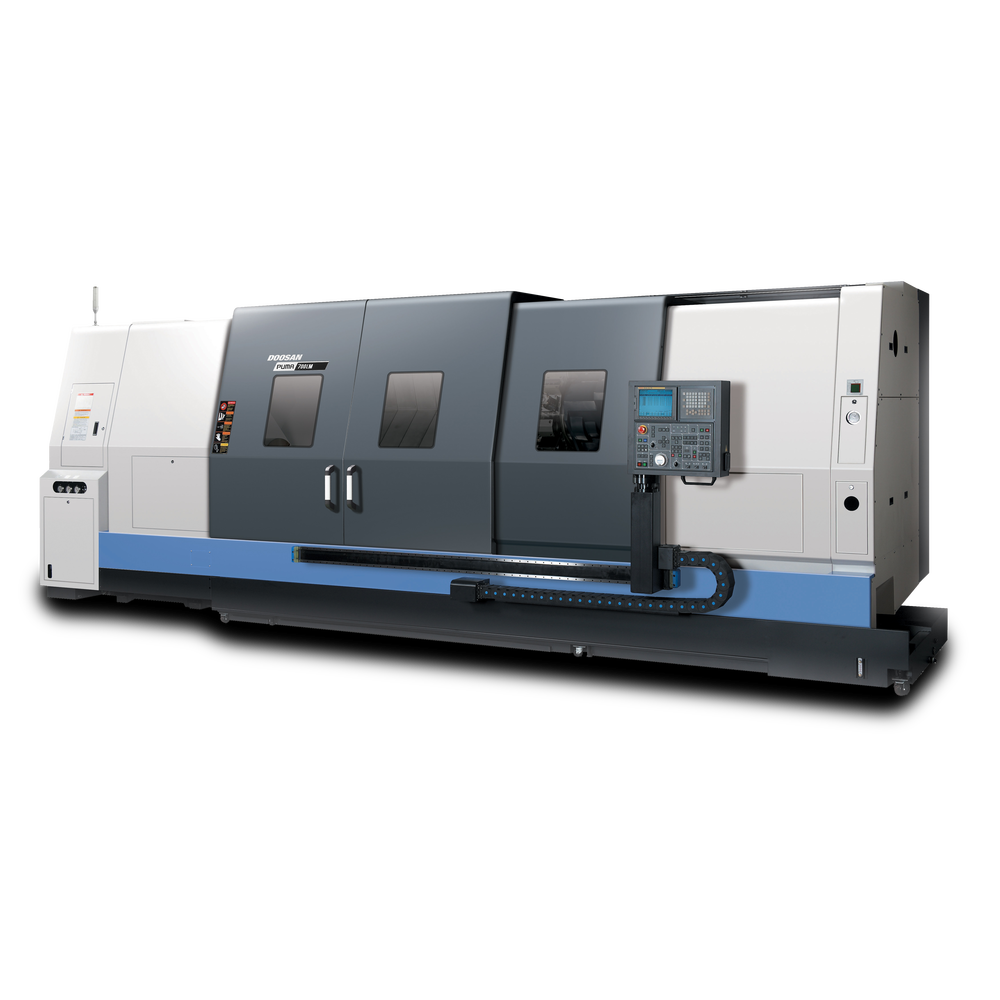

HORIZONTAL W/ MILLING

HORIZONTAL TURNING CENTERS

A CNC lathe or metalworking lathe is a large class of lathes designed for precisely machining relatively hard materials. They were originally designed to machine metals; however, with the advent of plastics and other materials, and with their inherent versatility, they are used in a wide range of applications, and a broad range of materials.

PUMA 1000

This is the box way HTC that lets you do it. The PUMA 1000 sports a 100 horsepower two-step gearbox that outputs over 8,880 ft-lb torque, plus a thru spindle bore hole of up to 22″. Translation: It takes on a multitude of shafts, rollers, rings and discs found all over the oil and gas, construction and aerospace industries.

Benefits of Turning Centers

Over 50 Years of Experience and Service!

You can depend on Adams Machinery for assistance in determining what machine will best fit your needs.