5-AXIS HORIZONTAL

ABOUT 5-AXIS TURNING CENTERS

A CNC lathe or metalworking lathe is a large class of lathes designed for precisely machining relatively hard materials. They were originally designed to machine metals; however, with the advent of plastics and other materials, and with their inherent versatility, they are used in a wide range of applications, and a broad range of materials.

PUMA MX

The PUMA MX1600ST, multitask milling/turning centers, are designed for heavy and interrupted cutting, longterm high accuracy, and superior surface finishes. High speed tool change and turret indexing, combined with fast rapid traverse rates minimize noncutting time. Caxis contouring, Yaxis offcenter and Baxis anyangle milling/drilling allow for single setup completion of highly complex workpieces. Samesize integral motors on both left and right spindles provide improved performance and flexibility. Multitasking capabilities increase productivity and provide for justintime production requirements by reducing lead time, changeover time, setup time, and time between operations.

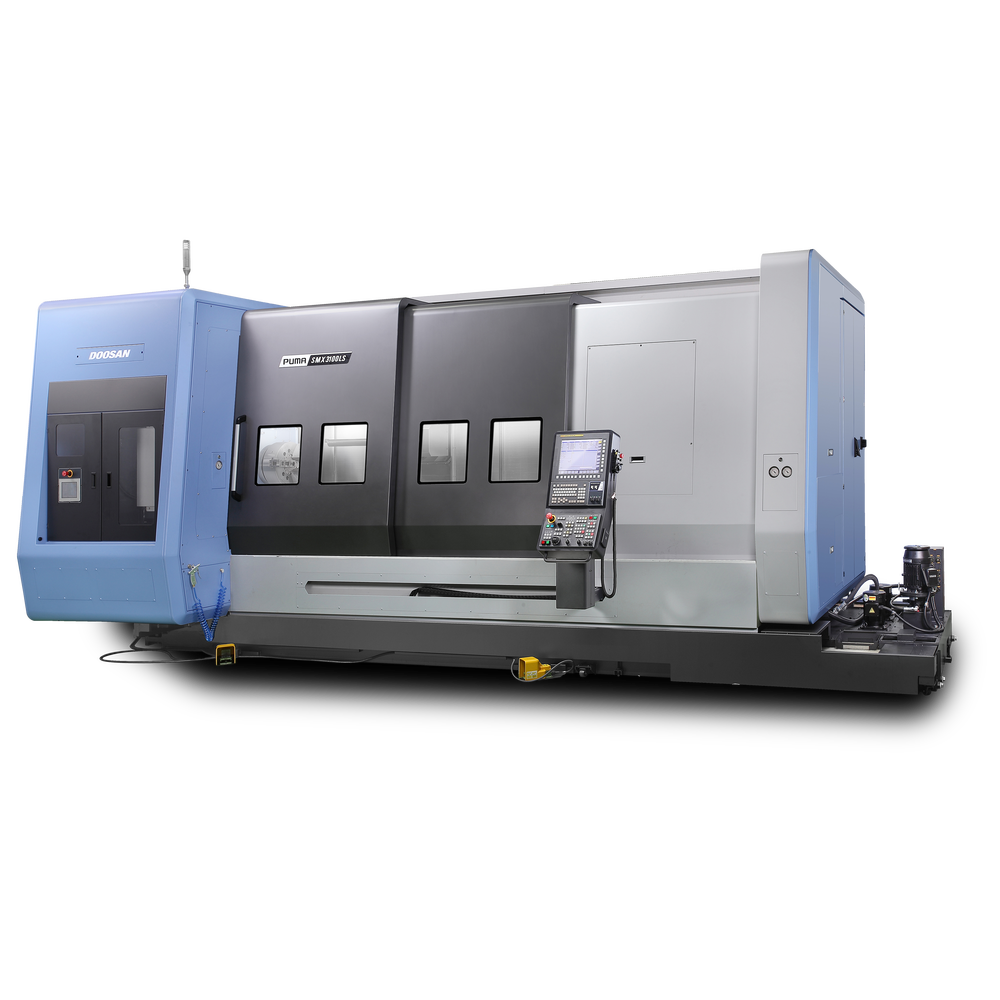

PUMA SMX

The PUMA SMX3100 multi-task milling/turning center, is designed for heavy and interrupted cutting, long-term high accuracy, and superior surface finishes. High speed tool change, combined with fast rapid traverse rates minimize non-cutting time. C-axis contouring, Y-axis off-center and B-axis any-angle milling/drilling allow for single set-up completion of highly complex workpieces. Multi-tasking capabilities increase productivity and provide for just-in-time production requirements by reducing lead time, changeover time, set-up time, and time between operations.

PUMA TT(SY)

The PUMA TT1500SY multi-task mill/turn centers are designed for long-term high accuracy, and superior surface finishes. High speed turret indexing and fast rapid traverse rates minimize non-cutting time. C-axis contouring and Y-axis off-center milling/drilling allow for single set-up and completion of highly complex workpieces. Same-size integral spindle motors on both spindles provide improved performance and flexibility. Multi-tasking capabilities increase productivity and provide for just-in-time production requirements by reducing lead time, changeover time, set-up time, and time between operations.

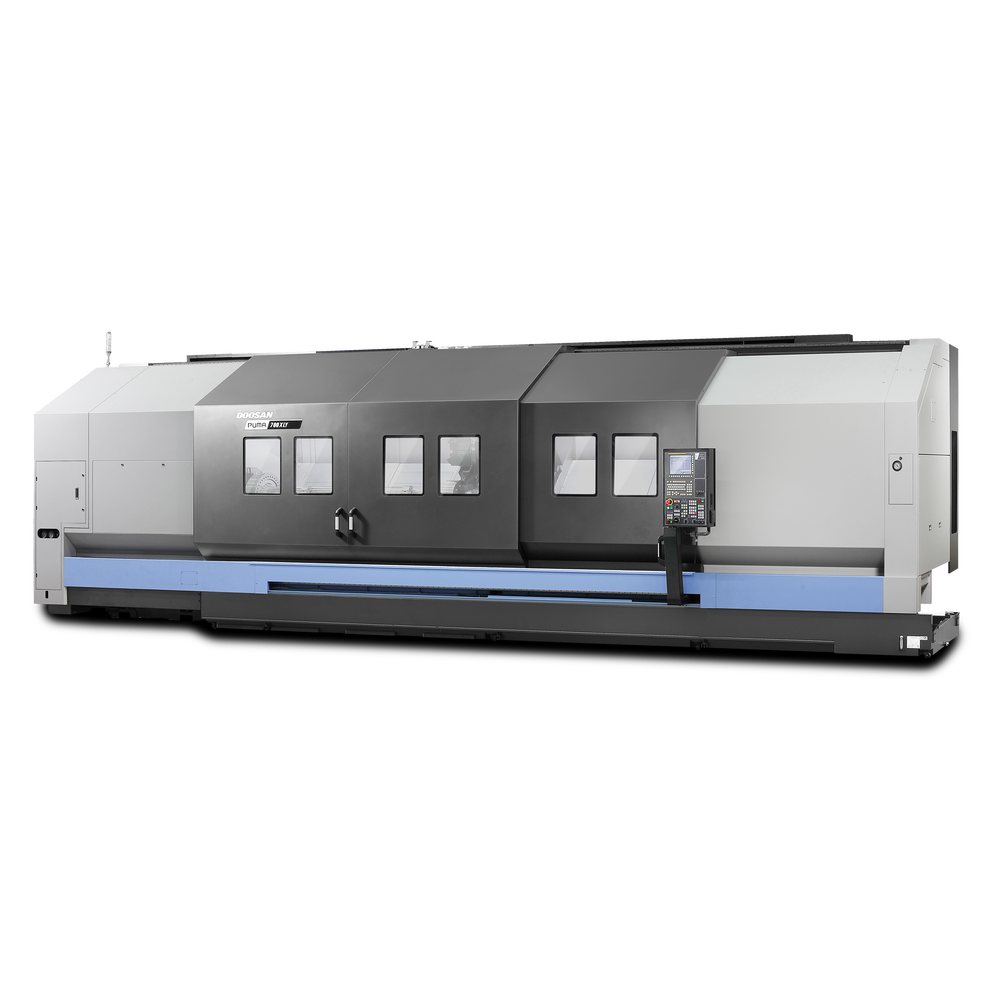

PUMA 700

Need large capacity? Look no further. If you machine pipes and flanges for the oil and gas, construction, aerospace or shipbuilding industries, the PUMA 700 Series is a true difference maker. Its turning diameter maxes out at 35.4″ and the turning length goes all the way up to 198.8″.

PUMA 2100/2600 W/ Y-AXIS

The Y-axis is a beautiful thing. Thanks to its integrated Y-axis and integral drive spindles, the PUMA 2100/2600(II) lets you handle the part from beginning to end on one machine. Put simply, it’s a productivity godsend.

PUMA 5100 W/ Y AXIS

Get more power and more torque. From the moment it’s installed, the PUMA 5100 brings high power, heavy duty cutting to your shop floor. The stable box guideway and its two-speed gearbox with high torque spindle motors create an instant productivity upgrade.

LYNX 2100 W/ Y-AXIS

The third axis opens up new cutting possibilities. With the addition of the Y-axis, drilling, grooving and radial cuts on the outer diameter of the bar are a walk in the park. Same story for drilling, surface milling and radial cuts on the end surface of the bar. Machine potential is maximized.

Benefits of Turning Centers

Over 50 Years of Experience and Service!

You can depend on Adams Machinery for assistance in determining what machine will best fit your needs.