HORIZONTAL W/ Y-AXIS

Y-AXIS TURNING CENTERS

A CNC lathe or metalworking lathe is a large class of lathes designed for precisely machining relatively hard materials. They were originally designed to machine metals; however, with the advent of plastics and other materials, and with their inherent versatility, they are used in a wide range of applications, and a broad range of materials.

LYNX 2100/2600

The third axis opens up new cutting possibilities. With the addition of the Y-axis, drilling, grooving and radial cuts on the outer diameter of the bar are a walk in the park. Same story for drilling, surface milling and radial cuts on the end surface of the bar. Machine potential is maximized.

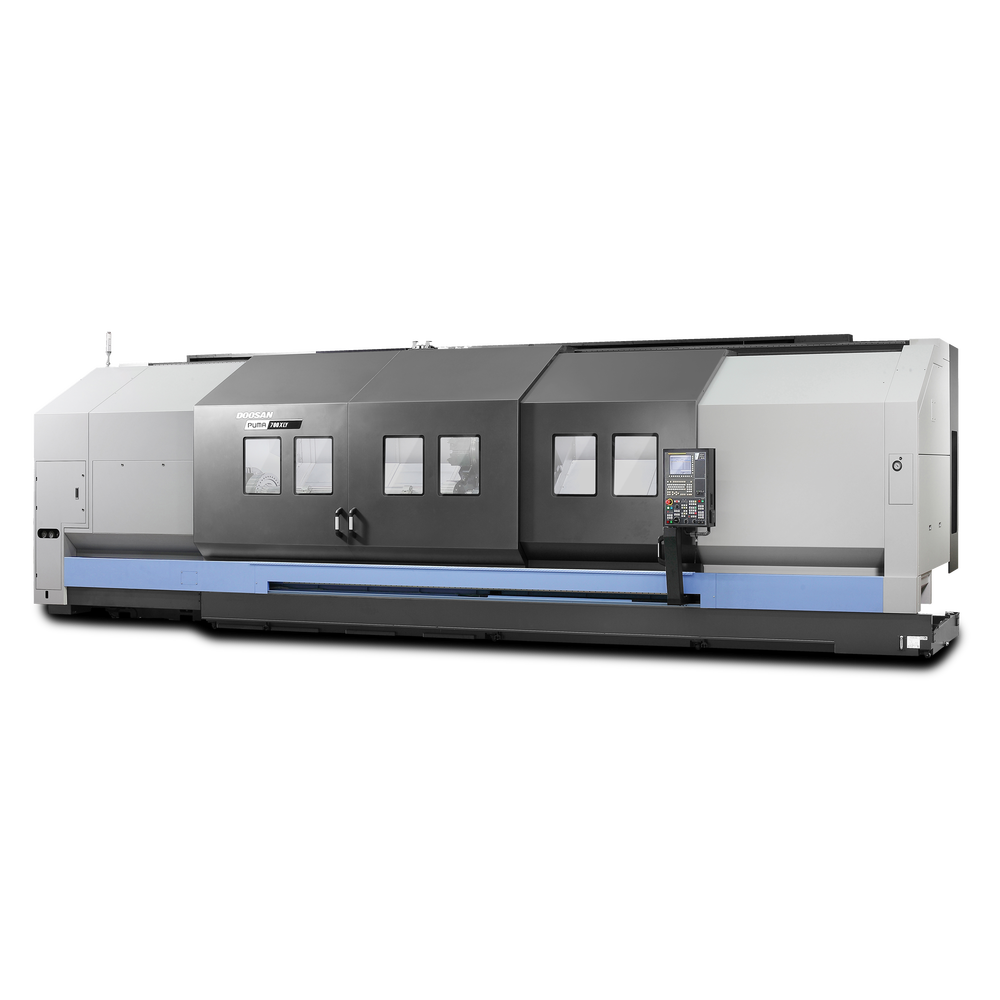

PUMA 700

If you need large capacity, the Puma 700 is for you. Those who machine pipes and flanges for oil and gas, construction, aerospace or shipbuilding know that the PUMA 700 Series is a true difference maker. Its turning diameter maxes out at 29.5″ and the turning length goes all the way up to 198.8″.

Benefits of Turning Centers

Over 50 Years of Experience and Service!

You can depend on Adams Machinery for assistance in determining what machine will best fit your needs.